Daawaha 625 Qiimaha Tuubbooyinka Gariiradda Birta Ah

Halabuurka Kiimikada, %

Qalabka Alloy 625 waa mid aan magnet-ka ahayn, austenitic, oo soo bandhigaya awoodda xajinta sare, samaynta, iyo naaxnimada.Sababtoo ah waxa ku jira nikkel-ka sarreeya, daawayntani waxay ku dhowdahay inay ka hortagto dillaaca cadaadiska-daxalka ee chloride ion, kaas oo sida caadiga ah laga helo biraha ku jira codsiyada biyaha badda sida kuwa kulaylka beddela, xirayaasha, iyo xiirada fiilada.

| Cr | Ni | Mo | Co + Nb | Ta | Al | Ti | C |

| 20.00-30.00 | Hadhaaga | 8.0-10.0 | 1.0 max | 3.15-4.15 | .40 max | .40 max | .10 max |

| Fe | Mn | Si | P | S |

| 5.0 max | .50 max | .50 max | .015 max | .015 max |

Waa maxay codsiyada loo isticmaalo Inconel 625?

- Inconel 625 waxaa inta badan lagu isticmaalaa warshadaha Aerospace

- Nidaamyada marinnada diyaaradaha

- Nidaamyada qiiqa matoorka jet

- Nidaamyada riixista-reverser engine

- Qalab gaar ah oo biyaha badda ah

- Qalabka habka kiimikada

Tilmaamaha ASTM

| Pipe Smls | Dhuumaha alxanka | Tube Smls | Tube Alxan | Xaashi/Saxaamo | Baar | Been abuurasho | Ku habboon | Silig |

| B444 | B705 | B444 | B704 | B443 | B446 | - | - | - |

Guryaha Makaanikada

| Heerkulka ° F | Xasilloonida (psi) | .2% Waxsoosaarka (psi) | Kordhinta 2 "(%) |

| 70 | 144,000 | 84,000 | 44 |

| 400 | 134,000 | 66,000 | 45 |

| 600 | 132,000 | 63,000 | 42.5 |

| 800 | 131,500 | 61,000 | 45 |

| 1000 | 130,000 | 60,500 | 48 |

| 1200 | 119,000 | 60,000 | 34 |

| 1400 | 78,000 | 58,500 | 59 |

| 1600 | 40,000 | 39,000 | 117 |

Inconel 625 barta dhalaalaysa

| Meesha dhalaalaysa | 1290 - 1350 °C | 2350 - 2460 °F |

Inconel 625 U dhigma

| HEERKA | SHAQADA NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| Inconel 625 | 2.4856 | N06625 | NCF 625 | NA 21 | ХН75МБТЮ | NC22DNB4MNiCr22Mo9Nb | NiCr23Fe |

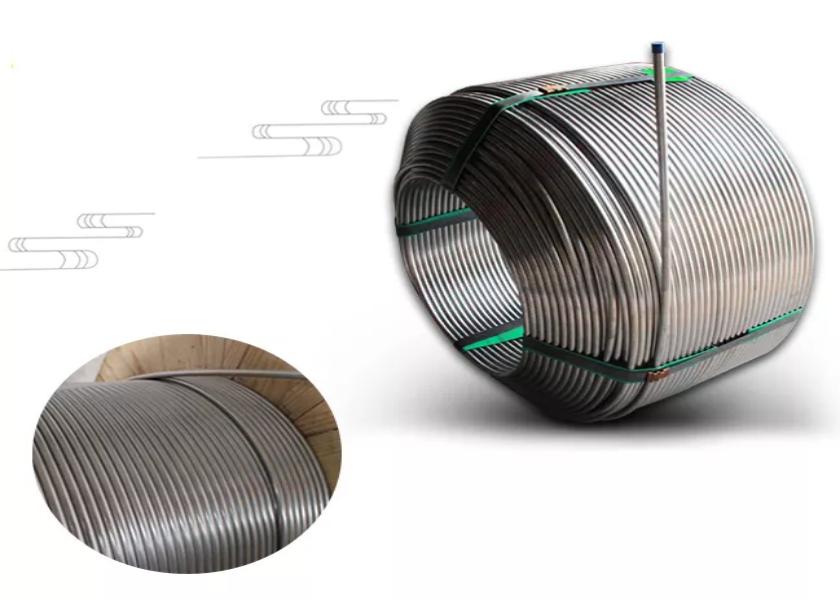

Alloy 625 Tuubooyinka

Alloy 625 waa austenitic nikkel-chromium-molybdenum superalloy caan ku ah u adkaysiga daxalka dillaacsan iyo oksaydheynta heerkulka sare leh.Heerkulkani wuxuu u dhexeeyaa laga bilaabo cryogenic ilaa heerkul aad u kulul oo ah 1,800F.Habdhaqanka iyo ka kooban kiimikaad ee fasalkan ayaa ka dhigaya mid ku habboon codsiyada nukliyeerka iyo hawada hawada.Sidoo kale, marka lagu daro niobium, daawaynta 625 tubbada waxay isku helaysaa awood korodhay oo aan lahayn daawaynta kulaylka.Gurigani wuxuu ka dhigayaa darajada ikhtiyaarka ugu fiican ee wax-soo-saarka.

Tilmaamaha Alaabta

ASTM B444 / ASME SB444 / NACE MR0175

Baaxadda cabbirka

| Dhexroor ka baxsan (OD) | Dhumucda darbiga |

| .375"-.750" | .035”-.095” |

Shuruudaha Kiimikada

Alloy 625 (UNS N06625)

Halabuurka %

| C Kaarboon | Mn Manganese | Si Silikoon | P Fosfooraska | Cr Chromium | Nb+Ta Niobium-Tantalum | Co Cobalt | Mo Molybdenum | Fe Birta | Al Aluminium | Ti Titanium | Ni Nikkel |

| 0.10 max | 0.50 max | 0.50 max | 0.015 max | 20.0-23.0 | 3.15–4.15 | 1.0 max | 8.0-10.0 | 5.0 max | 0.40 max | 0.40 max | 58.0 daqiiqo |

Dulqaadyada cabbirka

| OD | Dulqaadka OD | Dulqaadka gidaarka |

| .375"-0.500" marka laga reebo | +.004”/-.000” | ± 10% |

| 0.500"-1.250" marka laga reebo | +.005”/-.000” | ± 10% |

Guryaha Makaanikada

| Xoogga Wax-soo-saarka: | 60 ksi min |

| Xoogga Jilitaanka: | 120 ksi min |

| Dheeraynta (min 2"): | 30% |

Sawirrada Warshadda

Kormeer

Raridda & Baakaynta

Warbixinta Imtixaanka