Alloy 600 Steel Gariiradda Tubiyaha Qiimaha

Halabuurka Kiimikada, %

Codsiyada daxalka caadiga ah waxaa ka mid ah wax soo saarka titanium dioxide (dariiqa chloride), syntheses perchlorethylene, vinyl chloride monomer (VCM), iyo magnesium chloride.Alloy 600 waxaa loo isticmaalaa wax soo saarka kiimikada iyo cuntada iyo kaydinta, daawaynta kulaylka,condensers phenol, samaynta saabuunta, khudradda iyo weelasha acid dufan iyo qaar kale oo badan.

| Ni + Co | Cr | Fe | C | Mn | S | Si | Cu |

| 72.0 daqiiqo | 14.0-17.0 | 6.0-10.0 | .15 max | 1.00 max | .015 max | .50 max | .50 max |

Waa maxay codsiyada loo isticmaalo Inconel 600?

- Warshadaha kiimikada

- Hawada hawada

- warshadaha kulaylka lagu daweeyo

- Warshadaha saxarada iyo waraaqaha

- Habaynta cuntada

- Injineerinka Nukliyeerka

- Qaybaha marawaxadaha gaaska

Tilmaamaha ASTM

| Pipe Smls | Dhuumaha alxanka | Tube Smls | Tube Alxan | Xaashi/Saxaamo | Baar | Been abuurasho | Ku habboon | Silig |

| B167 | B517 | B163 | B516 | B168 | B166 | B564 | B366 |

Guryaha Makaanikada

Heerkulka caadiga ah ee qolka guryaha ee alaabta la dajiyay

| Foomka Alaabta | Xaalad | Xoojinta (ksi) | .2% Wax-soo-saar (ksi) | Kordhinta (%) | Adag (HRB) |

| Usha & Baar | Qabow-la sawiray | 80-100 | 25-50 | 35-55 | 65-85 |

| Usha & Baar | Kulul-Dhamaystay | 80-100 | 30-50 | 35-55 | 65-85 |

| Tube & Dhuumaha | Kulul-Dhamaystay | 75-100 | 25-50 | 35*55 | - |

| Tube & Dhuumaha | Qabow-la sawiray | 80-100 | 25-50 | 35-55 | 88 Max |

| Saxan | Kulul-Gool | 80-105 | 30-50 | 35-55 | 65-85 |

| xaashi | Qabow-la sawiray | 80-100 | 30-45 | 35-55 | 88 Max |

Inconel 600 Meesha dhalaalaysa

| Curiyaha | Cufnaanta | Meesha dhalaalaysa | Xoogga Jilicsan | Xoogga Wax-soo-saarka (0.2% ka-baxsan) | Dheeraynta |

| Alloy 600 | 8.47 g/cm3 | 1413 °C (2580 °F) | Psi – 95,000 , MPa – 655 | Psi – 45,000 , MPa – 310 | 40% |

Inconel 600 oo u dhiganta

| HEERKA | SHAQADA NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| Alloy 600 | 2.4816 | N06600 | NCF 600 | NA 13 | МНЖМц 28-2,5-1,5 | NC15FE11M | NiCr15Fe |

Alloy 600 Tubing

Alloy 600 waa musharax aad u wanaagsan isticmaalka badan oo heerkulka aadka u sarreeya iyo jawi aad u daxaloobay.Isku darka nikkel iyo chromium waxay soo saartaa iska caabin adag oksidhis heerkulka shaqada.Heerkulkani wuxuu u dhaxayn karaa qaylo-dhaan ilaa heerkul kulul oo ah 2,000F.Maadada sare ee nikkel ee daawaha 400 waxa kale oo ay bixisaa iska caabin ku dhow-buuxa ah ee dildilaaca daxalka stress, kaas oo inta badan laga helo deegaanka chloride.

Waxaa muhiim ah in la ogaado in qaybta chromium ee astaanta kiimikaad ee daawaha ay suurtogal ka dhigayso in darajadu u adkaysato heerkulka sare.Qaab dhismeedka fiican ee tuubada qabow ee dhammaatay, sidoo kale, waxay keenaysaa iska caabbinta daxalka, kaas oo ay ku jiraan daal sare iyo qiyamka xoogga saameynta.

Tilmaamaha Alaabta

ASTM B163, B167 / ASME SB163 / NACE MR0175, MR0103

Baaxadda cabbirka

| Dhexroor ka baxsan (OD) | Dhumucda darbiga |

| .250”-.750” | .035”-.083” |

Shuruudaha Kiimikada

Alloy 600 (UNS N06600)

Halabuurka %

| Ni Nikkel | Cu Copper | Fe Birta | Mn Manganese | C Kaarboon | Si Silikoon | S Baaruud | Cr Chromium |

| 72.0 daqiiqo | 0.50 max | 6.00-10.00 | 1.00 max | 0.15 max | 0.50 max | 0.015 max | 14.0-17.0 |

Dulqaadyada cabbirka

| OD | Dulqaadka OD | Dulqaadka gidaarka |

| ≤ .500" marka laga reebo | +.005” | ± 12.5% |

| .500"-.750" marka laga reebo | +.005” | ± 12.5% |

Guryaha Makaanikada

| Xoogga Wax-soo-saarka: | 35 ksi min |

| Xoogga Jilitaanka: | 80 ksi min |

| Dheeraynta (min 2"): | 30% |

Farsamaynta

Alloy 600 si fudud ayaa loo alxan karaa habka caadiga ah.Maaraynta daawahaani waa mid aad u fiican, oo degan inta u dhaxaysa tamarta T303 iyo T304.

Sawirrada Warshadda

Kormeer

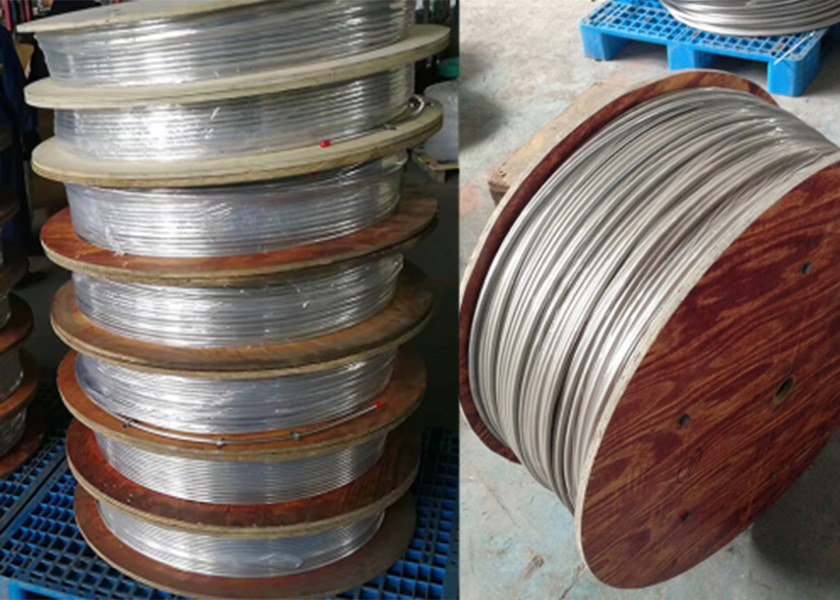

Raridda & Baakaynta

Warbixinta Imtixaanka