3003 tube aluminium duuban

Maxay 3003 uga dhigan tahay Gariiradda Aluminiumka?

Tirooyinka ku jira gariiradda aluminiumku waa koodhka alloy-ka, kaas oo kuu sheegaya waxa walxaha ku jira daawaha.Lambarka koowaad waxa uu tilmaamayaa curiye alloying-ka ugu muhiimsan.Nambarka labaad waxa uu tilmaamayaa kala duwanaanshaha daawaha (haddii uu ka duwan yahay eber), lambarka saddexaad iyo kan afraadna waxa uu tilmaamayaa taxanaheedii.

Marka loo eego 3003 gariiradda aluminiumka, nambarka ugu horreeya '3' wuxuu ka dhigan yahay inuu yahay alloy ka mid ah taxanaha manganese, '0' macnaheedu waa ma laha isbeddel, tirooyinka ugu dambeeya '03' waxay ka dhigan tahay inay ka timid taxanaha 3000.Nidaamkan lambarayntu waxa uu ku salaysan yahay Nidaamka Naqshadeynta Alloy-ka Caalamiga ah.

Guryaha 3003 Alloy Aluminum Coil

3003 gariiradda aluminiumku waxay leedahay xaddid ka kooban kiimiko oo ah 0.6 Silicon, 0.7 bir, 0.05-0.20 naxaas ah, 1-1.5 manganese, 0.10 zinc, iyo 0.15 laga soo bilaabo curiyeyaasha kale.

3003 aluminium waxay leedahay awood xajin ilaa 200MPa, hababka oo dhanna si sahal ah ayay alxan karaan.Waxay u adkeysaneysaa daxalka inta badan deegaannada marka laga reebo marka ay la kulmaan biyaha badda ama jawiga daxalka kale ee ay ku jiraan koloriin ama fluorine.

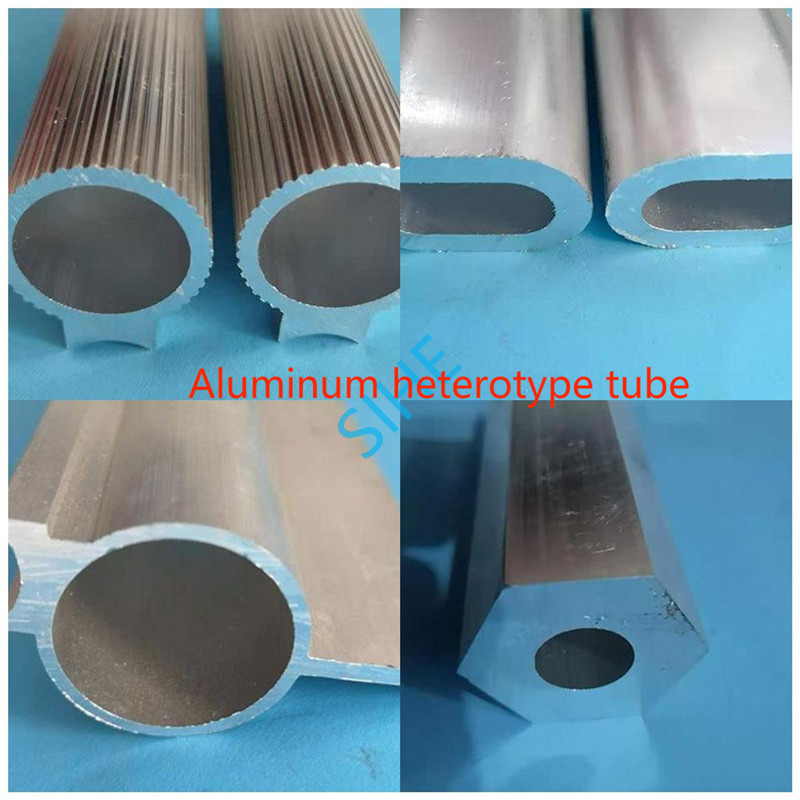

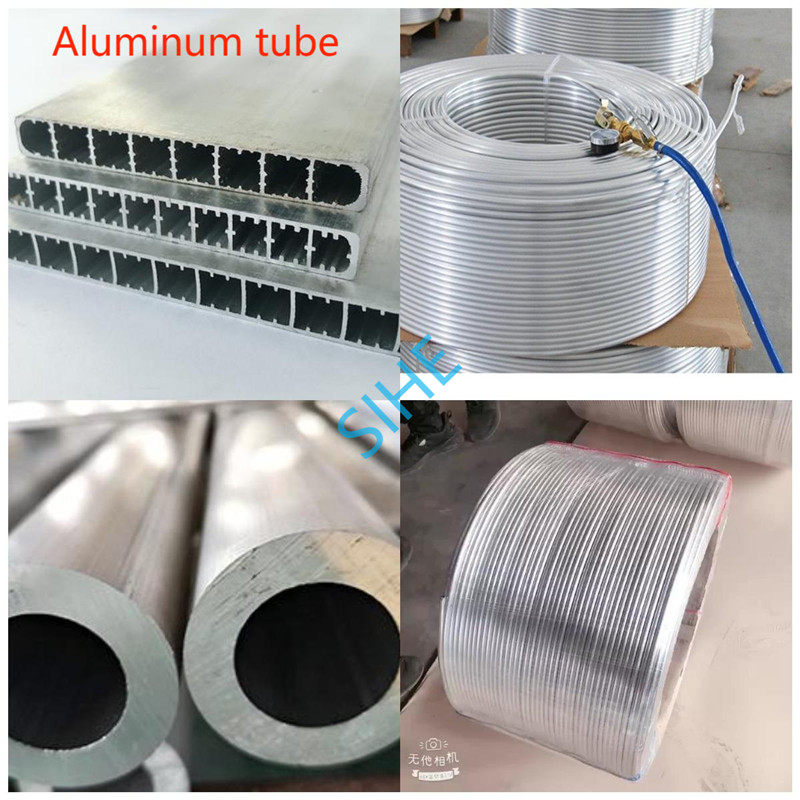

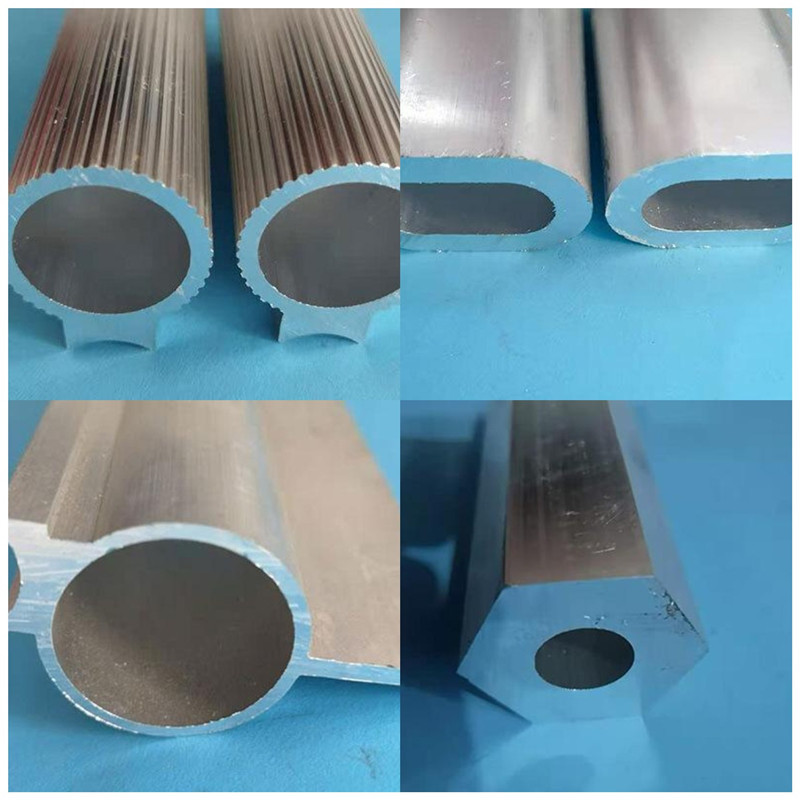

3003 gariiradda aluminiumka aluminiumka ah waxay ku yimaadaan qaabab iyo cabbirro kala duwan - oo u dhexeeya go'yaal dhumucdiisu tahay 0.4 mm ilaa 12 mm dhumucdiisuna waxay tahay tuubooyinka.Waxaa jira fursado badan marka la go'aaminayo qalabka mashruuc kasta.Waxa kale oo lagu heli karaa gariiradaha (isticmaalka warshadaha) iyo dhererka tooska ah (mashruuc ganacsi).

3003 Aluminium Coil Vs.3004 Aluminium gariiradda

3003 gariiradda aluminium iyo 3004 gariiradda aluminium ayaa labadaba loo isticmaalaa codsiyo kala duwan.In kasta oo ay isku mid yihiin, haddana isku mid ma aha, mid walbana faa’iidooyin iyo khasaare ayuu leeyahay.

Alloys 3003 iyo 3004 waxay la mid yihiin halabuurka, laakiin 3004 waxay leedahay 1% magnesium oo dheeri ah, taasoo ka dhigaysa xoogaa xoog badan.Tani waxay keenaysaa iska caabbinta daxalka ee ka wanaagsan marka ay la kulmaan jawiga aashitada, taasoo ka dhigaysa daawayntan mid ka qaalisan soo saarista 3003 alloys.

3003 aluminium aluminiumku wuxuu bixiyaa ductility ka wanaagsan kan 3004 alloy iyo alxanka sababtoo ah maadada magnesium ee hoose;si kastaba ha ahaatee, waxay leedahay miisaan ka hooseeya xoogga-miisaanka marka loo eego walxaha dambe sababtoo ah cufnaanta hoose.

Ku saabsan codsiga deegaanka, 3003 waa lagu daweyn karaa kulayl iyo qabow shaqayn, laakiin 3004 kaliya qabow ayaa shaqayn kara.

Tilmaamaha

| Alloy Maya | xanaaq | Tube Toosan | LWC | ||

| OD (mm) | WT (mm) | OD (mm) | WT | ||

| 1060 (L2) | R (H112) | 6 ~ 30 | 0.6 ~ 3 | 4 ~ 22 | 0.2 ~ 2 |

| M(O) | 6 ~ 30 | 0.6 ~ 3 | 4 ~ 22 | 0.2 ~ 2 | |

| H 14 | 6 ~ 30 | 0.6 ~ 3 | 4 ~ 22 | 0.2 ~ 2 | |

| 3A21 3003 3103 (LF21) | M(O) | 6 ~ 30 | 0.6 ~ 3 | 4 ~ 22 | 0.2 ~ 2 |

| H12 | 6 ~ 30 | 0.6 ~ 3 | 4 ~ 22 | 0.2 ~ 2 | |

| H14 | 6 ~ 30 | 0.6 ~ 3 | 4 ~ 22 | 0.2 ~ 2 | |

| H18 | 6 ~ 30 | 0.6 ~ 3 | 4 ~ 22 | 0.2 ~ 2 | |

| 6063 (LD31) | M(O) | 6 ~ 30 | 0.6 ~ 3 | 4 ~ 22 | 0.5 ~ 2 |

| T4 | 6 ~ 30 | 0.6 ~ 3 | 4 ~ 22 | 0.5 ~ 2 | |

| T6 | 6 ~ 30 | 0.6 ~ 3 | 4 ~ 22 | 0.5 ~ 2 | |

Qeexida Tube Aluminium ee Groove Gudaha (Xajmiga waa la beddeli karaa)

| Tilmaamaha (mm) | Dhumucda gidaarka (mm) | Dhererka Go'ay (mm) | Xagasha Helical(°) |

| 7 | 0.4-0.5 | 0.05-0.18 | 18 |

| 7.94 | 0.4-0.5 | 0.05-0.18 | 18 |

| 9.52 | 0.45-0.55 | 0.05-0.18 | 18 |

Qalabka Farsamada ee Tuubbada Aluminium Grooved Gudaha

| Qalab | Jilicsan | Heerka Kordhinta | Kordhinta Heerka |

| 3003 | 130MPA | 35 | 40 |

Tilmaamaha Xidhmada Gariiradda

| OD | 6.35 | 7.94 | 9.52 | 12.7 | 15.88 | 19.05 |

| Dhumucda darbiga | 0.7-1.0 | 0.8-1,2 | 0.8-1.2 | 1-1.5 | 1-1.5 | 1-1.5 |

Tirada Gurantee

| A1050 Aluminium Kiimikada Halabuurka | |||||||||

| Al | Si | Cu | Mg | Zn | Mn | Ti | V | Fe | Kuwo kale |

| 99.5-100 | 0 ~ 0.25 | 0 ~ 0.05 | 0 ~ 0.05 | 0 ~ 0.05 | 0 ~ 0.05 | 0 ~ 0.03 | 0 ~ 0.05 | 0 ~ 0.40 | 0 ~ 0.03 |

| A1060 Aluminium Kiimikada Halabuurka | |||||||||

| Al | Si | Cu | Mg | Zn | Mn | Ti | V | Fe | Kuwo kale |

| 99.6-100 | 0 ~ 0.25 | 0 ~ 0.05 | 0 ~ 0.03 | 0 ~ 0.05 | 0 ~ 0.03 | 0 ~ 0.03 | / | 0 ~ 0.35 | |

| A1070 Aluminium Kiimikada Halabuurka | |||||||||

| Al | Si | Cu | Mg | Zn | Mn | Ti | V | Fe | Kuwo kale |

| 99.7-100 | 0 ~ 0.2 | 0 ~ 0.04 | 0 ~ 0.03 | 0 ~ 0.04 | 0 ~ 0.03 | 0 ~ 0.03 | 0 ~ 0.05 | 0 ~ 0.25 | |

| A3003 Aluminium Curinta Kiimikada | |||||||

| Al | Si | Cu | Zn | Mn | Fe | Kuwo Kale Kaligeed | |

| kuwa kale | 0 ~ 0.6 | 0.05-0.20 | 0 ~ 0.1 | 1.0 ~ 1.5 | 0 ~ 0.70 | 0 ~ 0.05 | |

| Alloy | xanaaq | Tilmaamid | |||

| Dhumucda (mm) | Dhexroorka (mm) | Xoog xajin | Adag | ||

| 7075 7005(tube) | T5,T6,T9 | >0.5 | 5.0-80 | >310 Mpa | >140 |

| 6061 6063 (profile) | T5,T6 | >1.6 | 10-180 | >572 Mpa | HB90-110 |

| Dhererka: <6Meter | |||||

| XEERKA | dhumucdiisuna (mm) | XOOGGA JIDHKA | ELONGATION% | Heerka |

| T5 | 0.4-5 | 60-100 | ≥ 20 | GB/T3190-1996 |

| T6 | 0.5-6 | 70-120 | ≥ 4 | |

| T9 | 0.5-6 | 85-120 | ≥ 2 |

Alaabta aluminium