1070 tube aluminium duuban

Habka daaweynta kulaylka ee 1070

saliid deminta iyo xanaaqa.Awooda siligga birta ah ee noocan ah uma fiicna sida kan qubeyska rasaasta ee lagu daweeyay siliga birta, laakiin astaamuhu waa lebbis qiimuhuna waa yar yahay.Kadib samaynta duub qabowga, diiqada waa laga saarayaa.U jiid cabbirka la cayimay, ka dibna dib u celi.Tilmaamaha farsamada ee gariiradda jilicsan ayaa la heli karaa oo keliya ka dib marka la demiyo iyo heerkulka heerkulka dhexdhexaadka ah.

Tilmaamaha iyo Codsiyada 1070

Waxay leedahay sifooyinka caagga sare, caabbinta daxalka, conductivity wanaagsan iyo conductivity kulaylka, laakiin xoog hoose, aan la xoojiyey by daaweynta kulaylka, machinability liidata, oo aqbali kartaa alxanka xiriirka iyo alxanka gaaska.Samee isticmaalka dheeraad ah oo faa'iidooyinka ay si ay u soo saaraan qaybo ka mid ah qaab-dhismeedka gaar ah, sida bireed aluminium sameeyey gasket iyo capacitor, shabagga go'doomin tube elektarooniga ah, silig, cable ilaalinta cover, net, xudunta u ah silig iyo nidaamka hawo diyaarad qaybo ka mid ah iyo qaybaha qurxinta.

Tilmaamaha

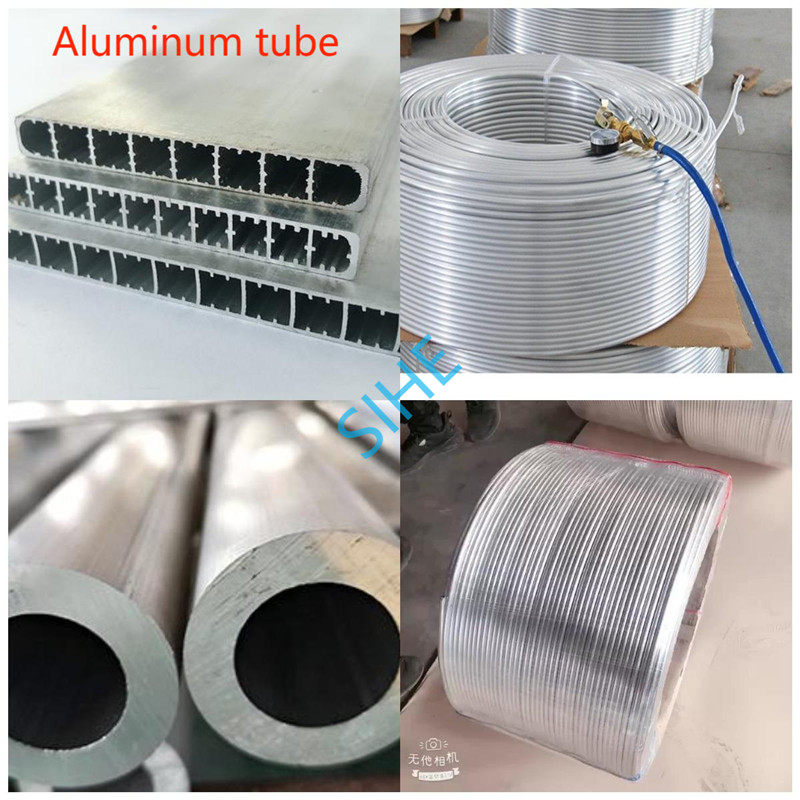

Tilmaamaha caadiga ah ee tuubada aluminiumka

| Alloy Maya | xanaaq | Tube Toosan | LWC | ||

| OD (mm) | WT (mm) | OD (mm) | WT | ||

| 1060 (L2) | R (H112) | 6 ~ 30 | 0.6 ~ 3 | 4 ~ 22 | 0.2 ~ 2 |

| M(O) | 6 ~ 30 | 0.6 ~ 3 | 4 ~ 22 | 0.2 ~ 2 | |

| H 14 | 6 ~ 30 | 0.6 ~ 3 | 4 ~ 22 | 0.2 ~ 2 | |

| 3A21 3003 3103 (LF21) | M(O) | 6 ~ 30 | 0.6 ~ 3 | 4 ~ 22 | 0.2 ~ 2 |

| H12 | 6 ~ 30 | 0.6 ~ 3 | 4 ~ 22 | 0.2 ~ 2 | |

| H14 | 6 ~ 30 | 0.6 ~ 3 | 4 ~ 22 | 0.2 ~ 2 | |

| H18 | 6 ~ 30 | 0.6 ~ 3 | 4 ~ 22 | 0.2 ~ 2 | |

| 6063 (LD31) | M(O) | 6 ~ 30 | 0.6 ~ 3 | 4 ~ 22 | 0.5 ~ 2 |

| T4 | 6 ~ 30 | 0.6 ~ 3 | 4 ~ 22 | 0.5 ~ 2 | |

| T6 | 6 ~ 30 | 0.6 ~ 3 | 4 ~ 22 | 0.5 ~ 2 | |

Qeexida Tube Aluminium ee Groove Gudaha (Xajmiga waa la beddeli karaa)

| Tilmaamaha (mm) | Dhumucda gidaarka (mm) | Dhererka Go'ay (mm) | Xagasha Helical(°) |

| 7 | 0.4-0.5 | 0.05-0.18 | 18 |

| 7.94 | 0.4-0.5 | 0.05-0.18 | 18 |

| 9.52 | 0.45-0.55 | 0.05-0.18 | 18 |

Qalabka Farsamada ee Tuubbada Aluminium Grooved Gudaha

| Qalab | Jilicsan | Heerka Kordhinta | Kordhinta Heerka |

| 3003 | 130MPA | 35 | 40 |

Tilmaamaha Xidhmada Gariiradda

| OD | 6.35 | 7.94 | 9.52 | 12.7 | 15.88 | 19.05 |

| Dhumucda darbiga | 0.7-1.0 | 0.8-1,2 | 0.8-1.2 | 1-1.5 | 1-1.5 | 1-1.5 |

dammaanad tiro

1) muuqaalka kore: oog siman oo nadiif ah oo aan dhammaan, xoqin, saliid wasakh ah ama oksaydheyn.

2) gees goynta: gees goyn nadiif ah oo aan burrs lahayn.

3) Hadafka tayada leh: heerka u qalma ee baadhista alaabta frist waa 98%.Ku qanacsanaanta macaamiisha 95%.Waxyaabaha: A1050, A1060, A1070, A3003, iyo wixii la mid ah

| A1050 Aluminium Kiimikada Halabuurka | |||||||||

| Al | Si | Cu | Mg | Zn | Mn | Ti | V | Fe | Kuwo kale |

| 99.5-100 | 0 ~ 0.25 | 0 ~ 0.05 | 0 ~ 0.05 | 0 ~ 0.05 | 0 ~ 0.05 | 0 ~ 0.03 | 0 ~ 0.05 | 0 ~ 0.40 | 0 ~ 0.03 |

| A1060 Aluminium Kiimikada Halabuurka | |||||||||

| Al | Si | Cu | Mg | Zn | Mn | Ti | V | Fe | Kuwo kale |

| 99.6-100 | 0 ~ 0.25 | 0 ~ 0.05 | 0 ~ 0.03 | 0 ~ 0.05 | 0 ~ 0.03 | 0 ~ 0.03 | / | 0 ~ 0.35 | |

| A1070 Aluminium Kiimikada Halabuurka | |||||||||

| Al | Si | Cu | Mg | Zn | Mn | Ti | V | Fe | Kuwo kale |

| 99.7-100 | 0 ~ 0.2 | 0 ~ 0.04 | 0 ~ 0.03 | 0 ~ 0.04 | 0 ~ 0.03 | 0 ~ 0.03 | 0 ~ 0.05 | 0 ~ 0.25 | |

| A3003 Aluminium Curinta Kiimikada | |||||||

| Al | Si | Cu | Zn | Mn | Fe | Kuwo Kale Kaligeed | |

| kuwa kale | 0 ~ 0.6 | 0.05-0.20 | 0 ~ 0.1 | 1.0 ~ 1.5 | 0 ~ 0.70 | 0 ~ 0.05 | |

| Alloy | xanaaq | Tilmaamid | |||

| Dhumucda (mm) | Dhexroorka (mm) | Xoog xajin | Adag | ||

| 7075 7005(tube) | T5,T6,T9 | >0.5 | 5.0-80 | >310 Mpa | >140 |

| 6061 6063 (profile) | T5,T6 | >1.6 | 10-180 | >572 Mpa | HB90-110 |

| Dhererka: <6Meter | |||||

| XEERKA | dhumucdiisuna (mm) | XOOGGA JIDHKA | ELONGATION% | Heerka |

| T5 | 0.4-5 | 60-100 | ≥ 20 | GB/T3190-1996 |

| T6 | 0.5-6 | 70-120 | ≥ 4 | |

| T9 | 0.5-6 | 85-120 | ≥ 2 |

Alaabta aluminium