1050 tube aluminium duuban

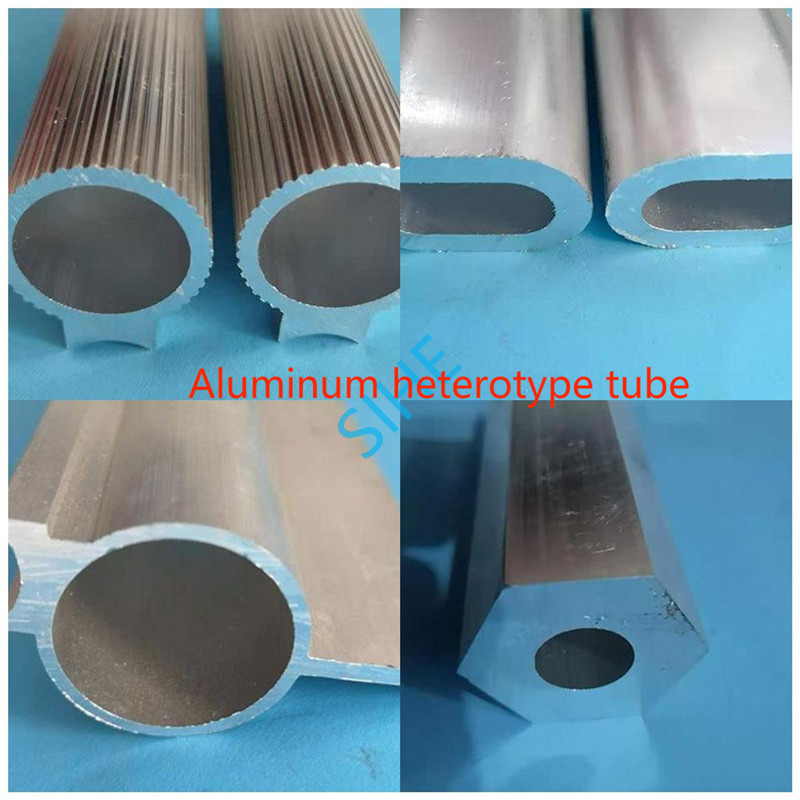

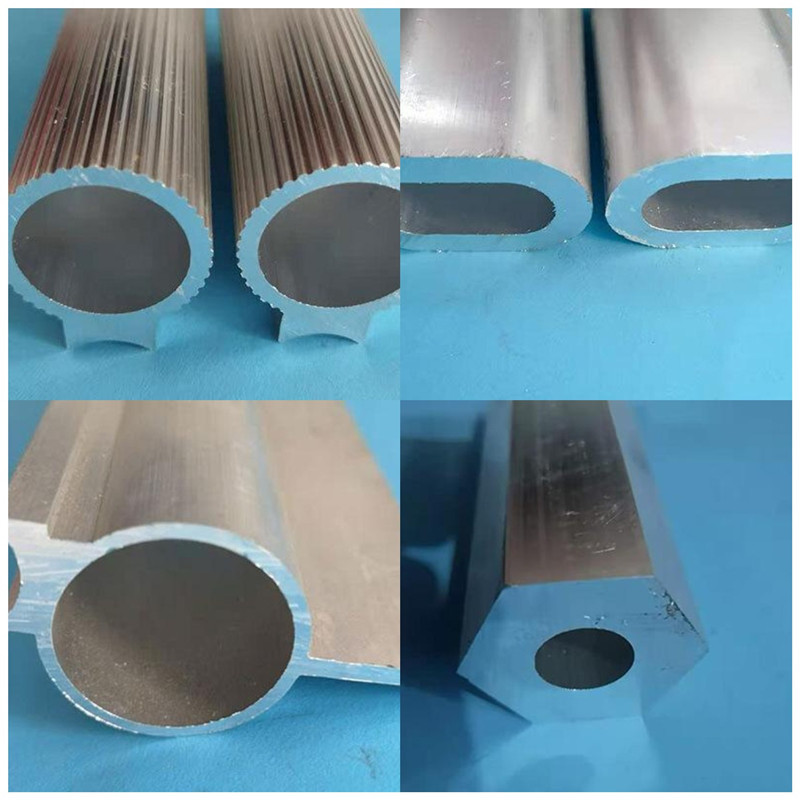

Tilmaamaha

Tilmaamaha caadiga ah ee tuubada aluminiumka

| Alloy Maya | xanaaq | Tube Toosan | LWC | ||

| OD (mm) | WT (mm) | OD (mm) | WT | ||

| 1060 (L2) | R (H112) | 6 ~ 30 | 0.6 ~ 3 | 4 ~ 22 | 0.2 ~ 2 |

| M(O) | 6 ~ 30 | 0.6 ~ 3 | 4 ~ 22 | 0.2 ~ 2 | |

| H 14 | 6 ~ 30 | 0.6 ~ 3 | 4 ~ 22 | 0.2 ~ 2 | |

| 3A21 3003 3103 (LF21) | M(O) | 6 ~ 30 | 0.6 ~ 3 | 4 ~ 22 | 0.2 ~ 2 |

| H12 | 6 ~ 30 | 0.6 ~ 3 | 4 ~ 22 | 0.2 ~ 2 | |

| H14 | 6 ~ 30 | 0.6 ~ 3 | 4 ~ 22 | 0.2 ~ 2 | |

| H18 | 6 ~ 30 | 0.6 ~ 3 | 4 ~ 22 | 0.2 ~ 2 | |

| 6063 (LD31) | M(O) | 6 ~ 30 | 0.6 ~ 3 | 4 ~ 22 | 0.5 ~ 2 |

| T4 | 6 ~ 30 | 0.6 ~ 3 | 4 ~ 22 | 0.5 ~ 2 | |

| T6 | 6 ~ 30 | 0.6 ~ 3 | 4 ~ 22 | 0.5 ~ 2 | |

Qeexida Tube Aluminium ee Groove Gudaha (Xajmiga waa la beddeli karaa)

| Tilmaamaha (mm) | Dhumucda gidaarka (mm) | Dhererka Go'ay (mm) | Xagasha Helical(°) |

| 7 | 0.4-0.5 | 0.05-0.18 | 18 |

| 7.94 | 0.4-0.5 | 0.05-0.18 | 18 |

| 9.52 | 0.45-0.55 | 0.05-0.18 | 18 |

Qalabka Farsamada ee Tuubbada Aluminium Grooved Gudaha

| Qalab | Jilicsan | Heerka Kordhinta | Kordhinta Heerka |

| 3003 | 130MPA | 35 | 40 |

Tilmaamaha Xidhmada Gariiradda

| OD | 6.35 | 7.94 | 9.52 | 12.7 | 15.88 | 19.05 |

| Dhumucda darbiga | 0.7-1.0 | 0.8-1,2 | 0.8-1.2 | 1-1.5 | 1-1.5 | 1-1.5 |

dammaanad tiro

1) muuqaalka kore: oog siman oo nadiif ah oo aan dhammaan, xoqin, saliid wasakh ah ama oksaydheyn.

2) gees goynta: gees goyn nadiif ah oo aan burrs lahayn.

3) Hadafka tayada leh: heerka u qalmida ee baadhista badeecada frist waa 98% qanacsanaanta macaamiisha 95%. Qalabka: A1050, A1060, A1070, A3003, iyo wixii la mid ah

| A1050 Aluminium Kiimikada Halabuurka | |||||||||

| Al | Si | Cu | Mg | Zn | Mn | Ti | V | Fe | Kuwo kale |

| 99.5-100 | 0 ~ 0.25 | 0 ~ 0.05 | 0 ~ 0.05 | 0 ~ 0.05 | 0 ~ 0.05 | 0 ~ 0.03 | 0 ~ 0.05 | 0 ~ 0.40 | 0 ~ 0.03 |

| A1060 Aluminium Kiimikada Halabuurka | |||||||||

| Al | Si | Cu | Mg | Zn | Mn | Ti | V | Fe | Kuwo kale |

| 99.6-100 | 0 ~ 0.25 | 0 ~ 0.05 | 0 ~ 0.03 | 0 ~ 0.05 | 0 ~ 0.03 | 0 ~ 0.03 | / | 0 ~ 0.35 | |

| A1070 Aluminium Kiimikada Halabuurka | |||||||||

| Al | Si | Cu | Mg | Zn | Mn | Ti | V | Fe | Kuwo kale |

| 99.7-100 | 0 ~ 0.2 | 0 ~ 0.04 | 0 ~ 0.03 | 0 ~ 0.04 | 0 ~ 0.03 | 0 ~ 0.03 | 0 ~ 0.05 | 0 ~ 0.25 | |

| A3003 Aluminium Curinta Kiimikada | |||||||

| Al | Si | Cu | Zn | Mn | Fe | Kuwo Kale Kaligeed | |

| kuwa kale | 0 ~ 0.6 | 0.05-0.20 | 0 ~ 0.1 | 1.0 ~ 1.5 | 0 ~ 0.70 | 0 ~ 0.05 | |

| Alloy | xanaaq | Tilmaamid | |||

| Dhumucda (mm) | Dhexroorka (mm) | Xoog xajin | Adag | ||

| 7075 7005(tube) | T5,T6,T9 | >0.5 | 5.0-80 | >310 Mpa | >140 |

| 6061 6063 (profile) | T5,T6 | >1.6 | 10-180 | >572 Mpa | HB90-110 |

| Dhererka: <6Meter | |||||

| XEERKA | dhumucdiisuna (mm) | XOOGGA JIDHKA | ELONGATION% | Heerka |

| T5 | 0.4-5 | 60-100 | ≥ 20 | GB/T3190-1996 |

| T6 | 0.5-6 | 70-120 | ≥ 4 | |

| T9 | 0.5-6 | 85-120 | ≥ 2 |

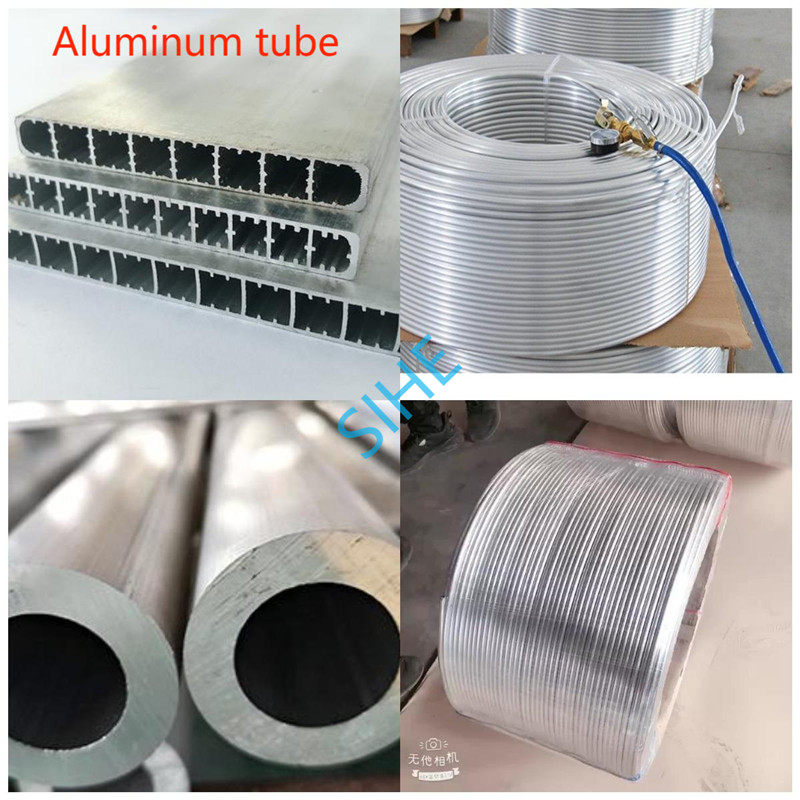

Alaabta aluminium

Halkan ku qor fariintaada oo noo soo dir